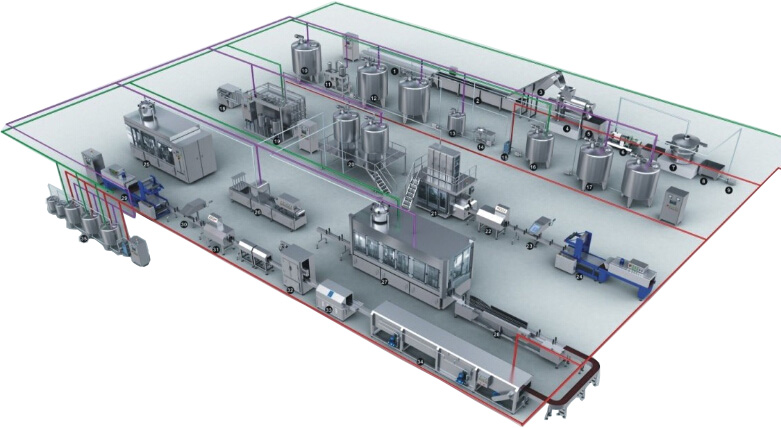

COMPLETE JUICE LINE

COMPLETE LINE SOLUTIONS FOR JUICE

Canadian Crystalline has conceptualized the most innovative method for the growing demand of complete Juice line solutions. Canadian Crystalline provides complete line solutions from processing Packaging design, Blowing, R-F-C, Kombopure®, Labeling, Date and Batch coding, Packing, Palletizing and Stretch rapping.Canadian Crystalline’s focus is on sustainable production and consistency of the product and to create solutions for enhancing Productivity, Hygiene and Line speed.

SPIRAL OPPORTUNITIES WITH Canadian Crystalline

Success in the Juice industry requires quality of product, highest consistency, maximized efficiency in production and low cost ensuring highest hygiene.

Canadian Crystalline complete line solutions support you in achieving the above easily and comfortably with its advanced technology and equipments augmented by strong service and spare support.

Canadian Crystalline helps you in design build and deliver the most impressive bottle design and packaging along with optimized production line from Start to End, ensuring the lowest foot print, compact design and enhanced efficiency.

Canadian Crystalline is always there to guide you with new market trends, demands and customer needs.

FLEXIBLE OPTIONS

Canadian Crystalline has various options for the customers from a standalone PET blowing machine coupled with R-F-C, Labeler and end of line solutions to the most advanced and efficient Kombo™ serves that integrates the blow fill and capping operators in one unit.

Kombopure ™ is a variable in Kombo™ series which ensures aseptic packing with the highest levels of sterility and hygiene of the product.

With Canadian Crystalline’s goal of simple innovations you can benefit from a large range of options and multiple integrations of equipment in lines with greatest simplicity and ease.

Canadian Crystalline also supports your equipment with strong service, training, upgradation and maintenance to ensure highest efficiency and least downtime in production.

All our new innovations can be upgraded into your existing lines effortlessly.

Canadian Crystalline Hot Fill Solutions High Sterility of Product

Sensitive products like Juice, Beverage, Nectars, Isotonic and Tea require a hot fill system to ensure its shelf life. Canadian Crystalline produces hot filling technology to support the requirement of such products. Filling temperature can range between 500 C to 900C depending on selection of packaging material. These lines can also be incorporated with aseptic features with a sterile filling environment.

COMPLETE LINE SOLUTIONS FOR JUICE - PET

Processing

Packaging

Blowing

Filling

Kombo

Labelling

Packing

Palletizing

Service

COMPLETE LINE SOLUTIONS FOR JUICE - GLASS

Processing

Washer

Filling

Labelling

Packing

Palletizing

Service