PET BLOWING MACHINE

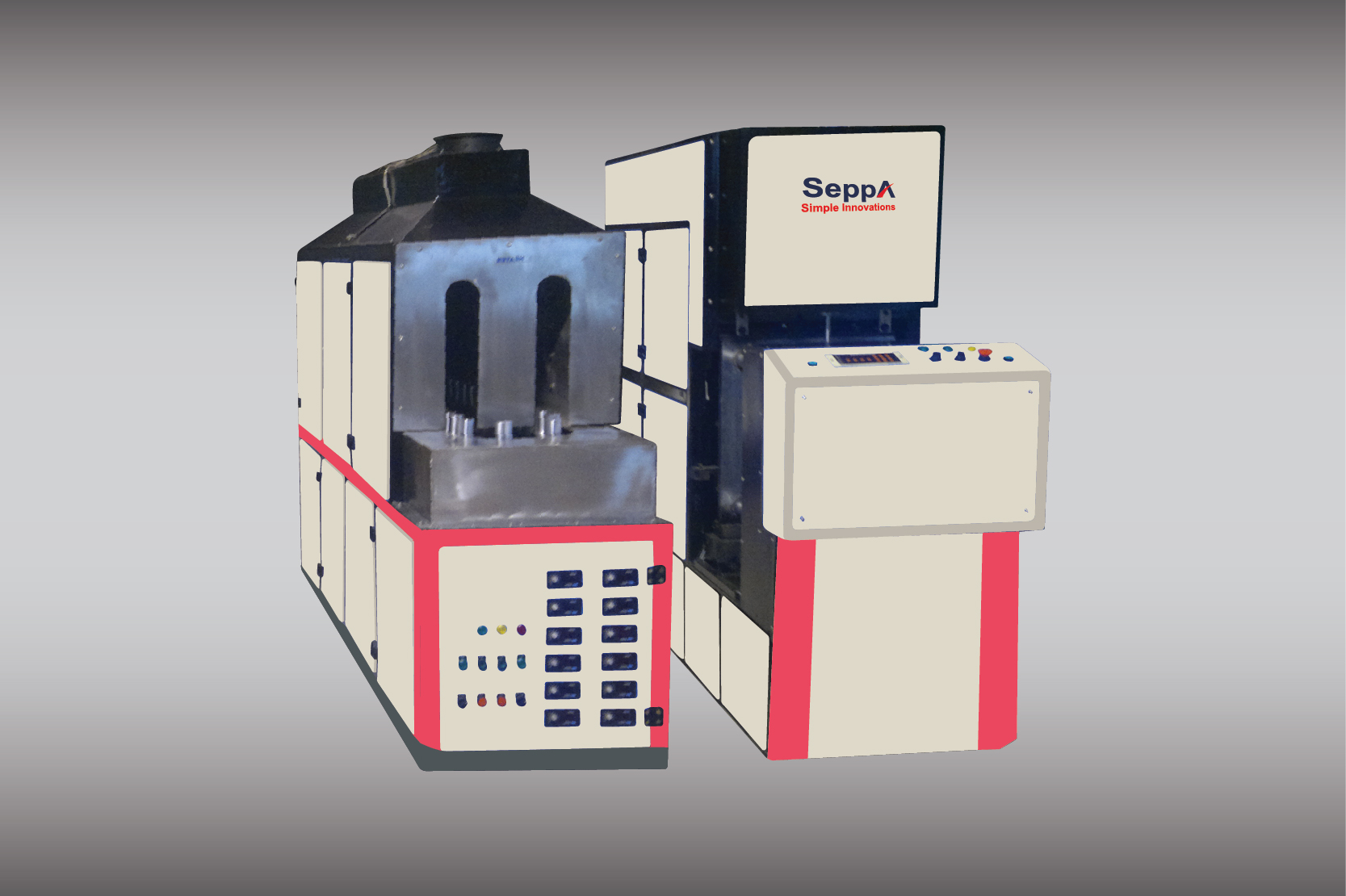

SEMI - AUTOMATIC PET BLOWING MACHINE

Canadian Crystalline has conceptualised the most innovative concepts to produce affordable low cost PET Blowing Machine for small and medium speed production.

Canadian Crystalline's focus is on sustainable production of the PET bottle creating solutions for enhancing productivity, low investment and bottle cost.

Canadian Crystalline designs are driven towards maximum uptime and reduced cost of production.

Canadian Crystalline produces a complete range of Semi-auto PET Blowing machines to produce PET bottles from 100 ml to 20 liters. The series are broken up into SSB 05A, B and C . Apart from this the latest most optimised auto drop system with options of preform unscrambler and auto preform loader to the heating system is incorporated in the SSB-D series.

The SSB -05 and SSB 20C series needed more human involvement in the process of producing PET bottles. The SSB – D series had reduced the human involvement or dependency by 90%. This has increased production speed optimised efficiency and reduced production cost.

CCWIL SSB - ( A - B - C - D ) SEMI - AUTO PNEUMATIC PET BLOWER

SSB -A ,B, C and D is a series of PET bottle blowing machines, characterised by its efficiency and reliability. All key functions this Series machines are handled by a state-of-the-art drive system utilising Geared motors and Pneumatics . Thanks to such innovative solutions as an efficient IR-based heating system, a recuperation system, special air collectors and blowing blocks, as well as the ability to blow bottles from ultra-light preforms, Canadian Crystalline machines enable stable and cost-effective production of high-quality PET bottles.

SSB - A , B ,C and D Series have efficient PET bottle production

As of today, this SSB-Series comprises 8 types of machines suitable for the production of PET bottles with a capacity ranging from 90ml to 2500 ml IN THE SSB 05A and B as also the SSB 2D and 4D series . SSB-05 B and SSB 2D offer the highest efficiency, enabling the manufacturing of about 1000 to 1200 of 500 ml bottles per hour, respectively. SSB-2D-AT is by far the most recognisable Canadian Crystalline product, which offers a nominal efficiency 1200 TO 1800 of 500 ml bottles per hour and 1000 to 1400 of 1,500 ml bottles per hour. Providing you with an easy-to-change neck format, blowing mould format change in 15 minutes, minimised bottle seam visibility, and blowout pressure and control, SSB-A ,B , C and D allows you to manufacture the perfect bottle with a one-of-a-kind shape and design. SSB-A,B,C and D Series bottle blowing machines are our response to the needs of the most demanding customers.