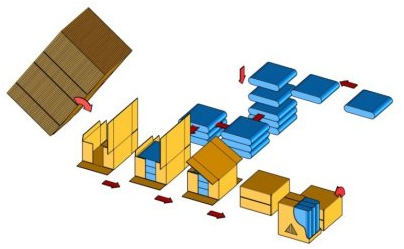

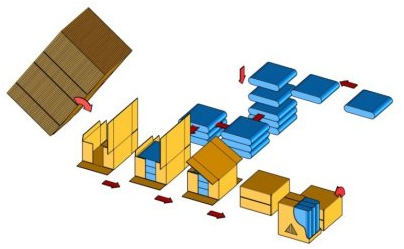

CARTON ERECTING MACHINES

Our carton erectors are designed to form carton boxes and seal the lower flaps with either self-adhesive tape or hot melt glue.The box drawing and opening unit is made up of a suction disk system, which is in constant movement. Lower flap bending is obtained mechanically by levers and guides

Canadian Crystalline are suppliers of carton erecting machines for various size boxes and for low to high speeds.We can supply machines with both PVC tape sealing as well as hot melt glue sealing of the bottom flaps

Carton Erector & Tape (PVC)

Carton Erector & Tape (PVC)

Carton Erector PV

Carton Erector PV

Carton Erector Hot Melt

Carton Erector Hot Melt

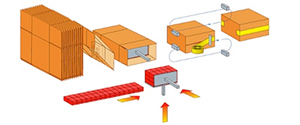

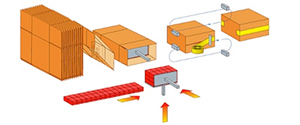

CARTON CLOSING MACHINES

Canadian Crystalline supplies carton sealing equipment for low and high speed outputs

We can offer both hot melt glueing and PVC tape sealing of the cartons.

Automatic Hot Melt Gluing Machine is suitable to close the upper and lower flaps of American carton boxes, already filled in, and to seal them by means of Hot Melt glue

The machine is complete with:

Spacing system for carton boxes.

Spacing system for carton boxes.

Adjustable device to draw carton boxes by their side, fold and press their flaps.

Adjustable device to draw carton boxes by their side, fold and press their flaps.

Nordson gluing unit

Nordson gluing unit

Safety guardst

Safety guardst

PVC Tape Case Sealer

PVC Tape Case Sealer

Carton Packing Station

Carton Packing Station

Hot Melt Carton Sealer

Hot Melt Carton Sealer

Automatic Hot Melt case sealer with side driven belts and manual dimensioning, suitable to seal the lower parts of boxes of the same size coming from filling line. It doesn’t require the presence of an operator.

The box coming from a filling station, with the bottom part sealed, is taken and driven through the driven belts inside the machine where injectors apply 4 strips of Hot Melt glue. The upper flaps, after being folded, are kept in pressure by a suitable presser until the next box arrives.

The Hot Melt sealer doesn’t require the presence of an operator except for the glue adjustments and feeding. It is equipped with an anti-accident guard with panels which prevents the operator from coming into contact with the moving parts or with high temperature parts.

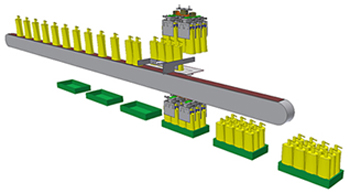

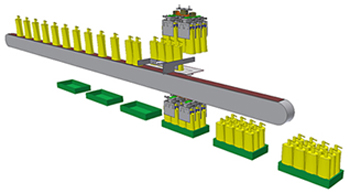

CARTON WRAPAROUND MACHINES

Our carton wraparound machines include automatic machines for the packaging of plastic, metal and glass containers in corrugated cardboard cases.

The trays can be octagonal or rectangular, with walls having either the same height or different heights.

The machine incorporates three / four types of washing:

a) The case packers can achieve an output up to 45 packs per minute, according to the machine model and to the product.

b) Pack collations can vary according to the containers shape and dimensions. In general, the most requested collations are: 2×3, 3×4 and 4×6.

Canadian Crystalline Wraparound Machine High Speed

Canadian Crystalline Wraparound Machine High Speed

Bottle Wraparound Machine

Bottle Wraparound Machine

Our Wraparound machines include automatic machines for the packaging of plastic, metal and glass containers in corrugated cardboard cases. The trays can be octagonal or rectangular, with walls having either the same height or different heights. Our case packers are equipped with a grouping system and can be supplied with in-line or 90

CASE PCKER – TOP LOADING / PICK & PLACE +

The Canadian Crystalline Pick and Place Case Packer does the automatic packaging of rigid containers the most varied formats, like bottles, jars, cans, trays, carton shells and packages, sachets and pillow bags.

The product’s handling is done through the Pick and Place arm, equipped with suction cups or grippers, according to the package shape. Its arm does a lateral movement for case packing, with a small foot-print, which saves room at the production line.

Pick and Place Case Packer receives pre-erected cases and products from the filling line, splits the products on rows according to the packing pattern and softly places products in the pre erected cases.

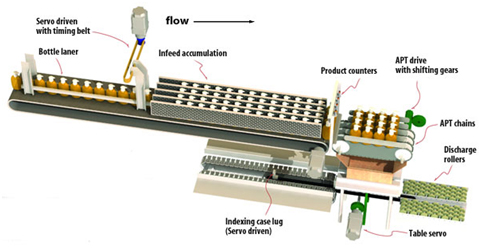

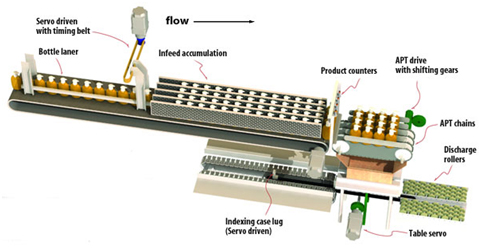

CASE PACKER – SIDE LOADING +

The Canadian Crystalline Side load case packers are designed to load products into an open case on its side.

Working with an in-feed system, the products are collated in the correct pack configuration and then loaded horizontally into the open case lying on its side.

Side load case packers are available in many frame sizes and we offer a range of in-feed systems for handling a variety of primary products such as cartons, pouches or trays.

With a compact footprint, side load case packers provide operators with floor level access inside the machine.

Size changes can be manually completed in less than 10 minutes without the need to change parts.

DROP CASE PACKER +

The Canadian Crystalline Drop Packer is a fully automatic machine that accepts erected corrugated trays / cartons, and loads them with containers, controlling both handle and label orientation. It delivers the fully loaded tray / carton to an output conveyor. The machine performs its function in response to the presence of product on the in feed conveyor and the supply of trays / cartons in the loading station.

The Drop Packer is a continuously operating packaging machine. Whether it is boxes, bottles, jars, cans, or cartons, it can pack virtually all conceivable products, thereby enabling outputs of up to 60 trays/cases per minute. The format-flexibility of the tray line provides the ability of producing open trays, trays with shoulder tabs, and shoulder trays. The modular design enables the use of the Tray Packer in the most versatile fields of operation. Excellent vision at each working station, optimum operator access and the extremely simple control unit is user friendly.

WRAP AROUND CASE PACKER +

The intermittent Wraparound Case Packers caters for speeds of up to 15 cases per minute. All Machines in the range feature Servo Drive Technology offering the customer State of the Art Performance.

The wraparound case packer is an intermittent motion machine able to pack bottles, jars, cans or packets into wraparound style cases. This machine features an individually designed product in feed system to meet customer specific requirements.

The unique dual servo driven case transfer system enables case length selection to be done via the operator interface screen, eliminating difficult mechanical size change adjustments. The HMI rotates about the centre line of the machine to provide operator control from either side of the machine.

This machine can be supplied to handle either Internal or External Glue Lap.

Full size guard doors on both sides of the machine offer complete access for operator intervention. Fully Automatic adjusting product paddles guarantee higher reliability and precision when changing to a new carton size.

Carton Erector & Tape (PVC)

Carton Erector & Tape (PVC)  Carton Erector PV

Carton Erector PV  Carton Erector Hot Melt

Carton Erector Hot Melt  Spacing system for carton boxes.

Spacing system for carton boxes. Adjustable device to draw carton boxes by their side, fold and press their flaps.

Adjustable device to draw carton boxes by their side, fold and press their flaps. Nordson gluing unit

Nordson gluing unit Safety guardst

Safety guardst PVC Tape Case Sealer

PVC Tape Case Sealer Carton Packing Station

Carton Packing Station Hot Melt Carton Sealer

Hot Melt Carton Sealer Canadian Crystalline Wraparound Machine High Speed

Canadian Crystalline Wraparound Machine High Speed  Bottle Wraparound Machine

Bottle Wraparound Machine