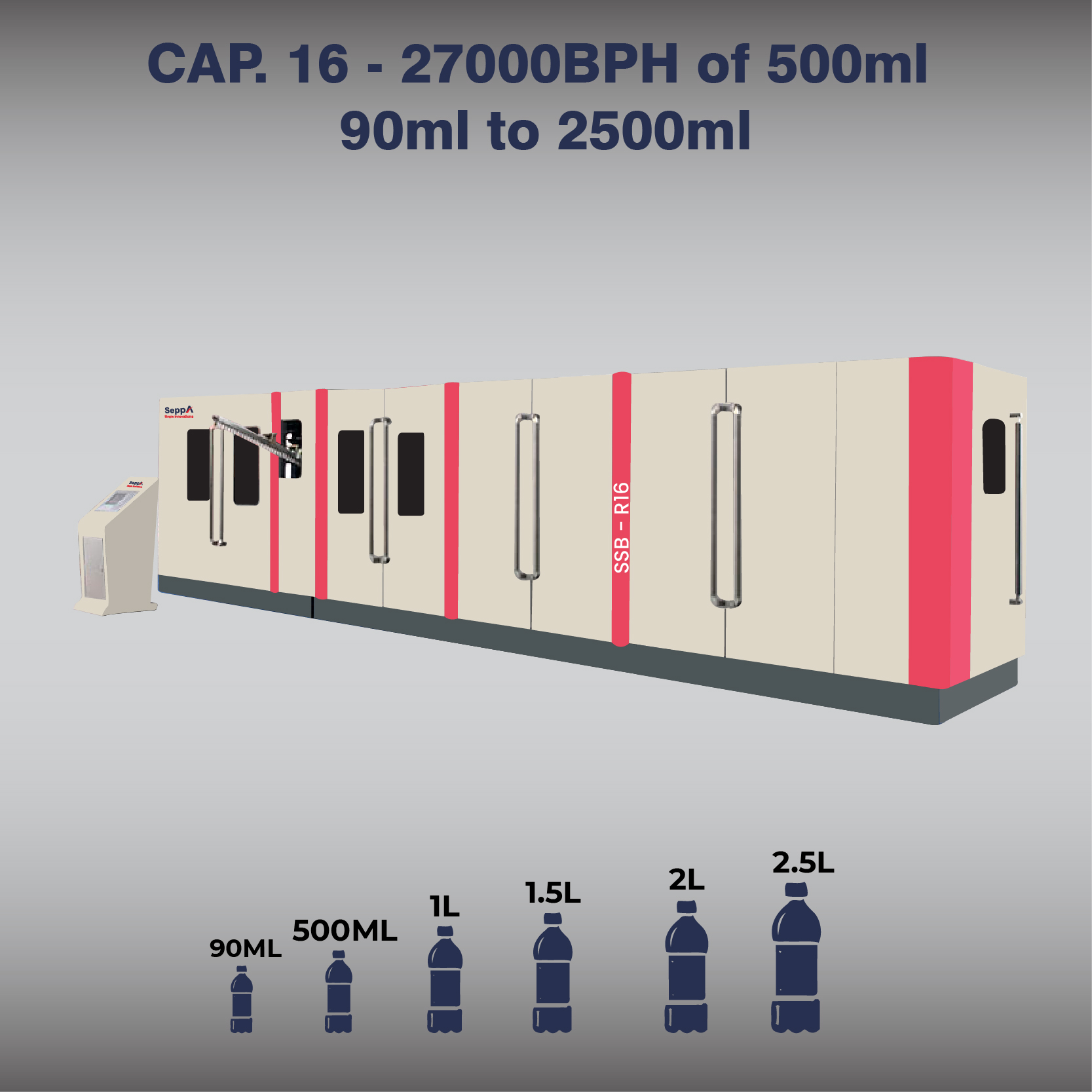

PET BLOWING MACHINE

CCWIL SSB - R - ROTARY PET BLOWER

SSB - R series fully automatic rotary stretch blow moulding machine ensures high efficiency and performance and combines a comprehensive bottle solution development program to devise the best solution for high speed. The machine features, high-tech component, stable running, low power and air consumption, minimised maintenance which could meet relevant national food sanitation requirements and shows the leading status domestically. The machine covers an extremely board range of applications including still or carbonated water, soft drinks, edible oil, juice and sport drinks, tea and milk or milk drinks.

Preforms loading Star-wheel preform feeding system:

- Pneumatic gate releases preforms into the star-wheel.

- Preform is loaded onto the spindle (and not vice-versa) by means of cam track-driven grippers.

- No chain axial movement.

- Quick star-wheel changeover.

Preforms handling and transport chain:

- Simple chain in special plastic material. No maintenance cost and down time.

- No rotation of chain around its axis and no up and down movement to collect the preform.

- Dry operation (no grease).

- Quick tool-free spindle changeover when handling different preform neck.

- Flexibility to change chain pitch to blow bottle neck up to 43 mm.

- low maintenance cost

Preforms loading Star-wheel preform feeding system

- Innovative ventilation through the lamps to maximise heat transfer by radiation (convection minimisation).

- Neck ventilation inside heating oven for effective neck cooling of light-weight preforms

- 8-10 lamps -additional lampcan be added for longer preforms.

- Low thermal inertia: heat process consistency and quick cold start-up.

- Low oven temperature: low power consumption.

PREFORMS & BOTTLES TRANSFER

- Simple transfer movement.

- simple cam design.

- Smaller diameter.

- Preforms & bottles centrifugal forces are very low.

- Soft and smooth manipulation of preform and bottle necks.

- Very easy adjustment.

- Removal of speed limiting factor.

STRETCH - BLOWING

- Reduced pitch between two molds: relevant space saving for the blowing wheel compared to equivalent machines.

- Smaller diameter.

- Lower inertial load and peripheral speed.

- Simplified transfer wheel, small diameter, lower peripheral speeds.

- Easy to maintain - accessibility to key elements.

- Shell mould, computable to mount major competitors moulds.

- Quick moulds change-over

Canadian Crystalline rotary stretch-blow moulders, available both in "stand alone" version and in "combi" version, ensure high performances in the stretch blow-moulding of PET, rPET and PP bottles, mainly used for the food, beverage and detergent industries.

Due to high-tech components, low maintenance and running costs and great quality/price ratio, Canadian Crystalline machines are the best solution for producing plastic containers with different capacities and shapes, both simple and complex.

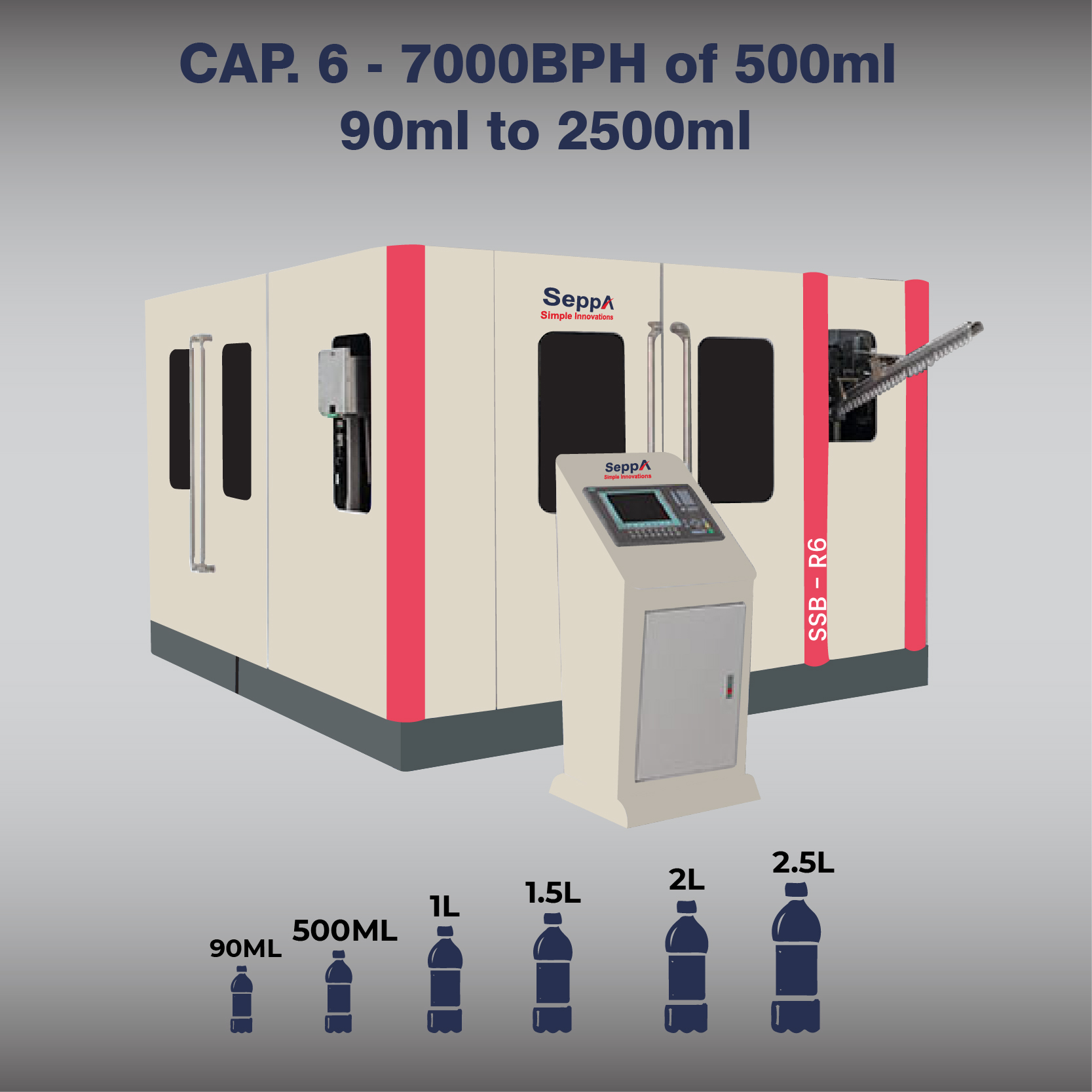

- * SSB-R 2 and SSB-R4 models, from 2 to 4 cavities, ideal for the production of PET/rPET/PP bottles with a maximum output of 2,300 bph/cavity*;

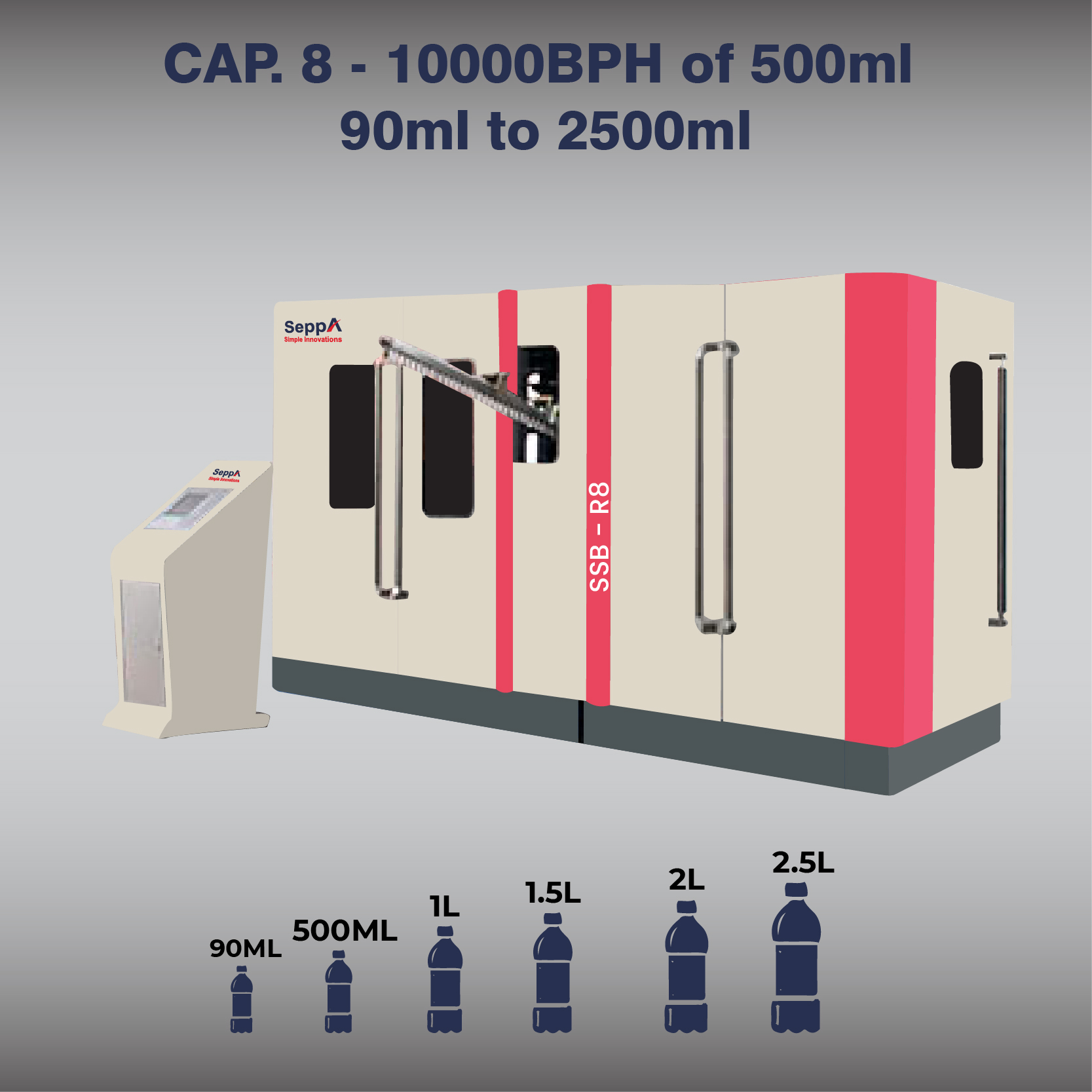

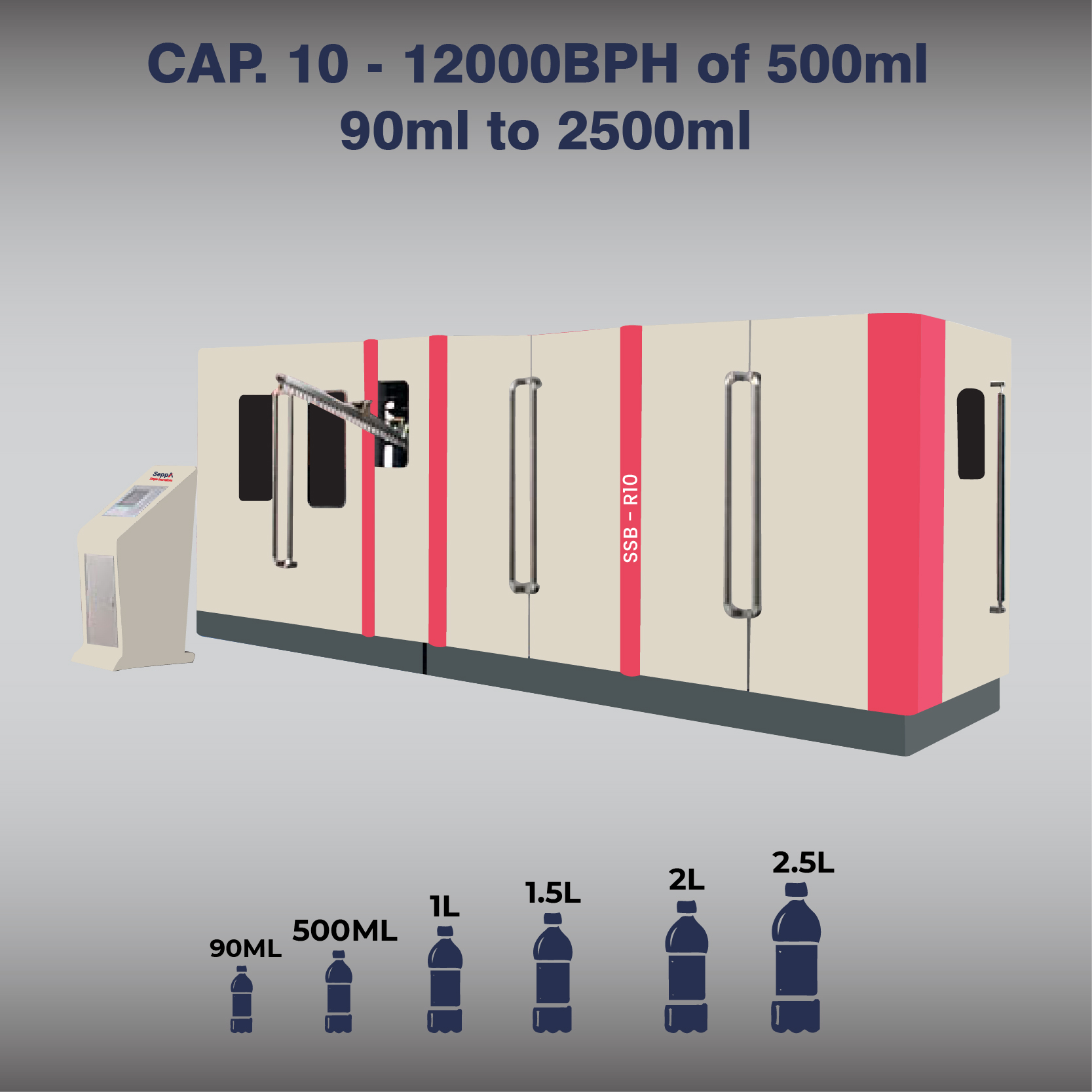

- * SSB-R6 to SSB-R10 models, with 6 and 10 cavities, ideal for the production of PET/rPET/PP bottles with a maximum output of 2,500 bph/cavity*;

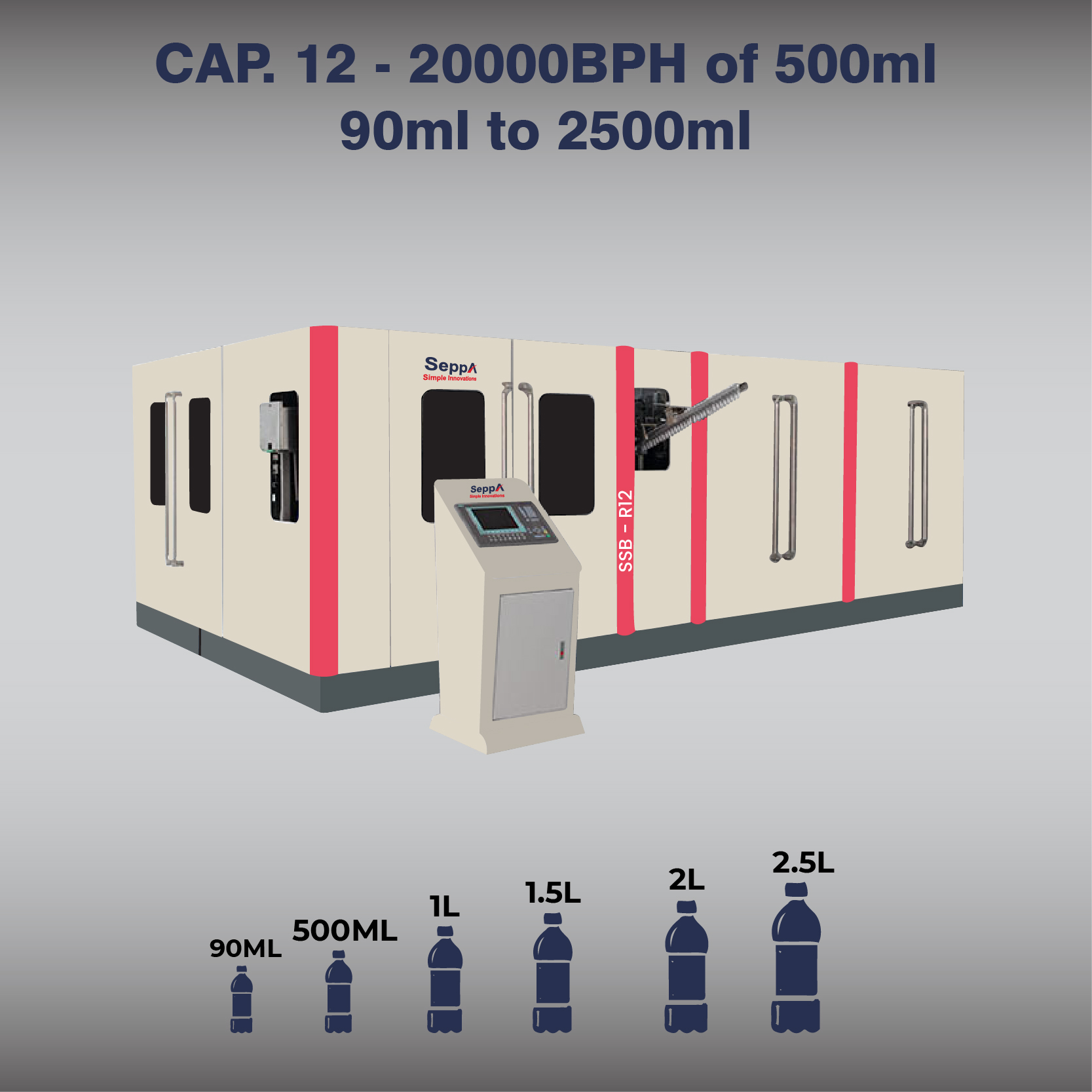

- * SSB-R12 TO SSB-R 16 models, from 12 to 16 cavities, ideal for the production of PET/rPET/PP bottles with a maximum output of 2,300 bph/cavity*;

- * SSB-R3-HC TO SSB- R6-HC (High Capacity) , from 3 to 6 cavities, specifically designed for the production of PET/rPET/PP high-capacity containers with a maximum output of 1,200 bph/cavity*.

- * according to the selected machine model and to the type of container.*